Profile System

Development of an integrated base frame construction

Development of aluminium profile system as substituon for a construction in steel.

The customer had two different profiles which have been manufactured in two different places and the "wedding" of them was again a third working step.

By integrating them in one profile-system we reduced the working time by the factor 10.

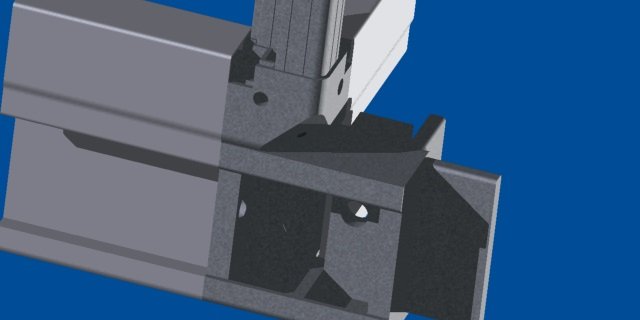

I developed the alu profile by using Autocad Inventor and the Nastran tool.

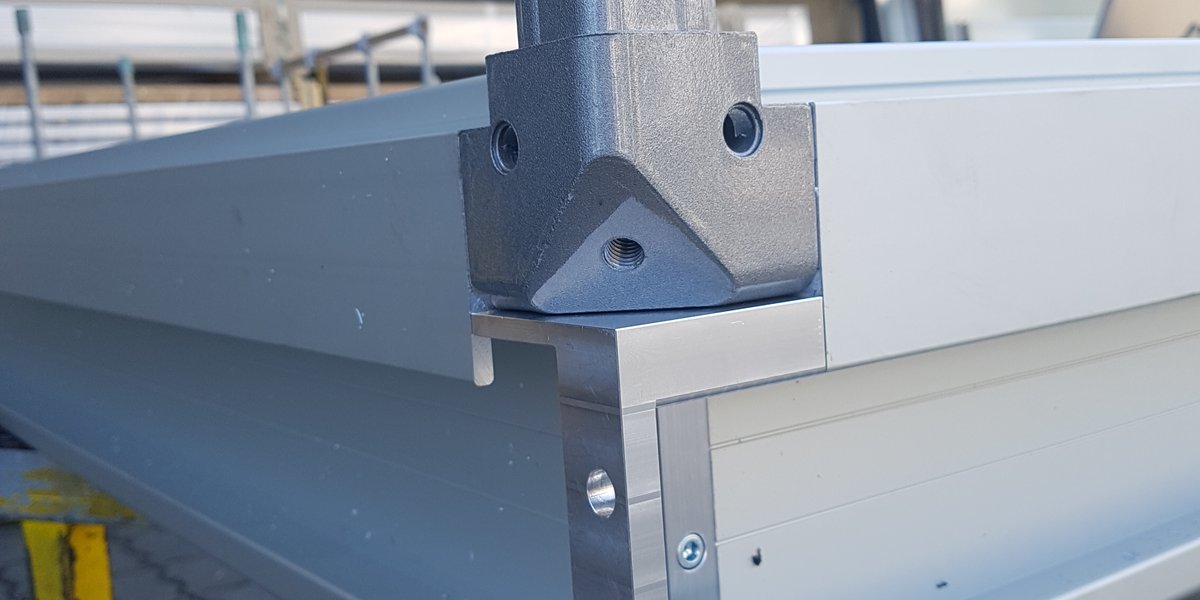

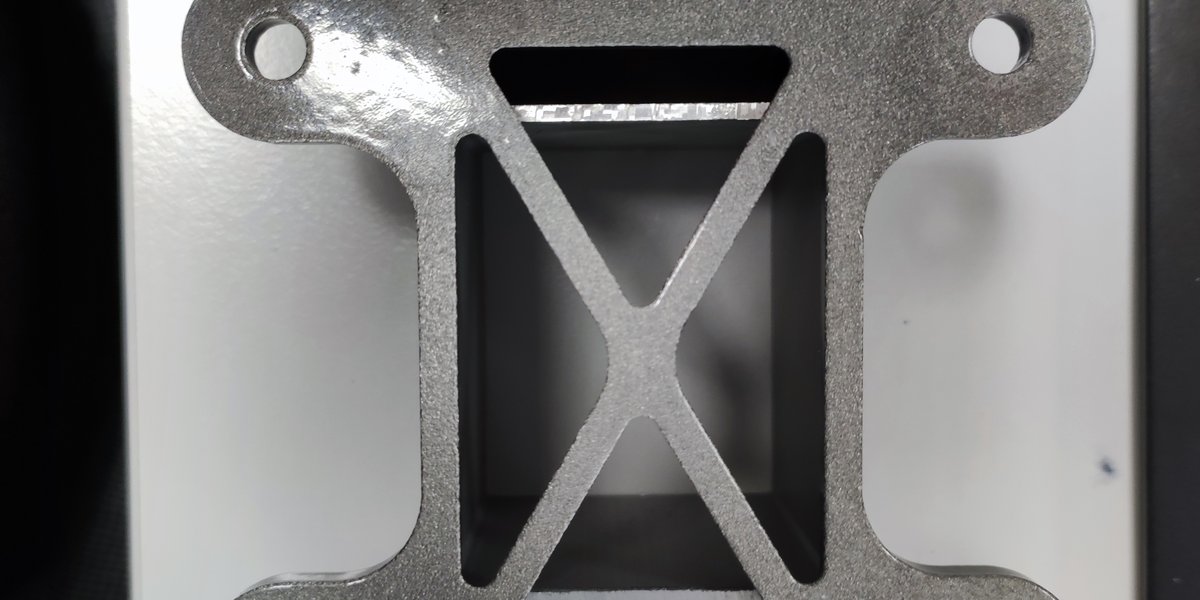

Together with the team we developed the profile outside and inside and also the connectors.

I did the first tests by using rapid prototyping technologies such as STL.

We tested the prototypes by using traditional milling and drilling.

We searched different suppliers, worked with them in order to find a producable version.

Key benefits:

- Acceleration of production and thus improved satisfaction of the market.

- Substitution of steel frames at lower costs due to handling (integration of base frame in equipment frame, fewer production steps).

- Easier assembly of covers for the base frame (cabling in the base frame). Cabling in the base frame with connector solution (simplified assembly of covers, routing of cables across several parts of the unit)

- Improved and attractive appearance

- Higher resistance of the aluminum to corrosion

- Base frame anodized (no more rust in the base frame)